The ZG series of underground diaphragm wall hydraulic grabs can be widely used in the construction of foundation pit support, rail transit, dyke seepage prevention, dock cofferdam, underground space of urban infrastructure construction, etc.

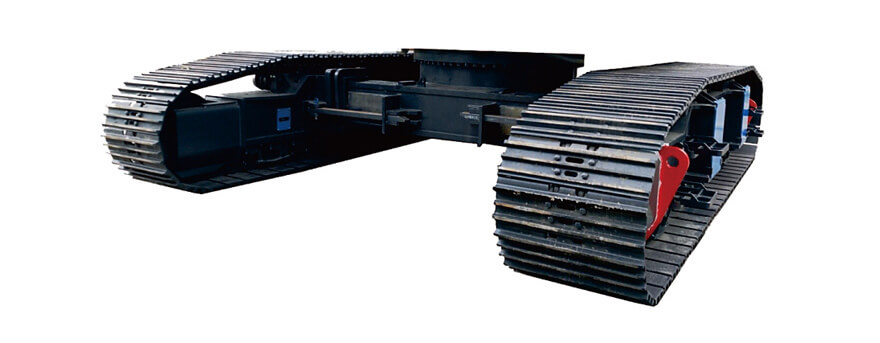

The ZU120 telescopic chassis designed and manufactured by the company is easy to expand and disassemble; the H beam flange cylinder is enlarged: the structural strength is significantly improved.

Range: 3450~4600mm;

Track width: 800mm

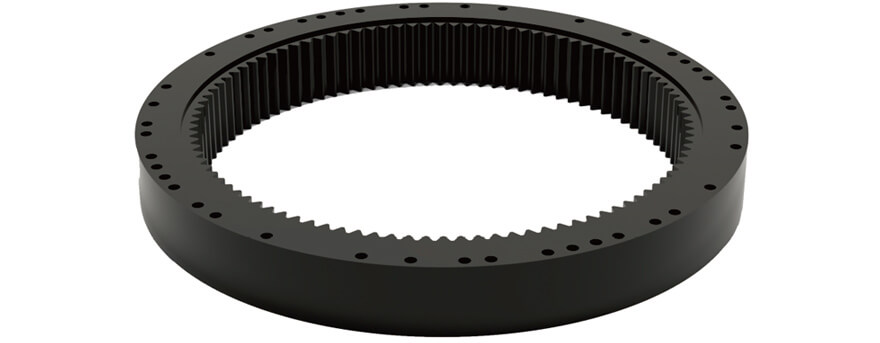

The slewing bearing supplier of the world-renowned brand is selected: the three-row roller slewing bearing from Rothe Erde, Germany, with long service life.

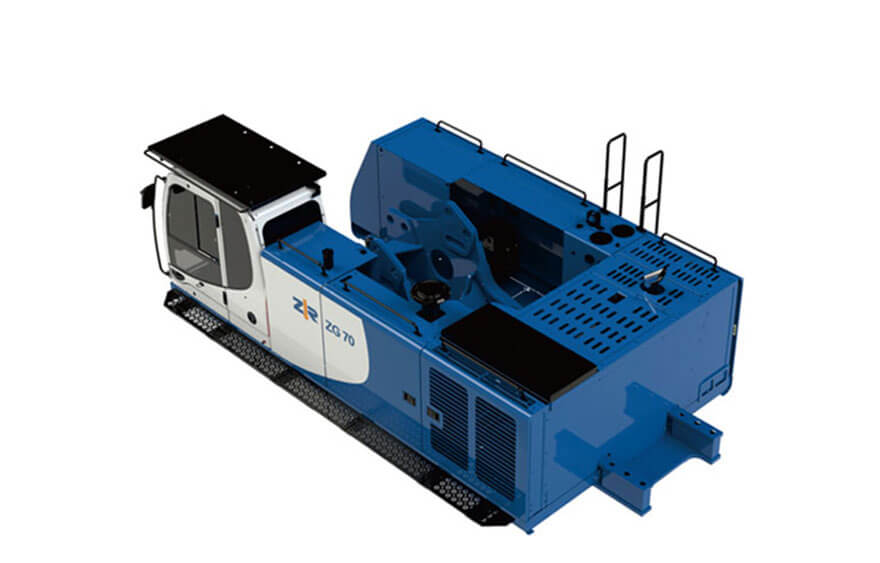

The chassis jointly developed with Hyundai (Jiangsu) has a large space, comfortable, novel overall structure design and convenient maintenance:

The chassis is widened and the hoist is built-in;

The position of the cab is moved forward, which makes it easier for the operator to see the working surface, and it is safer to add a top protective cover;

The new structure large-capacity hydraulic oil tank has good heat dissipation, anti-pollution, external filter element, easy to replace;

The 700-liter large-capacity fuel tank can work continuously for more than 14 hours. The filter element is externally installed and easy to replace;

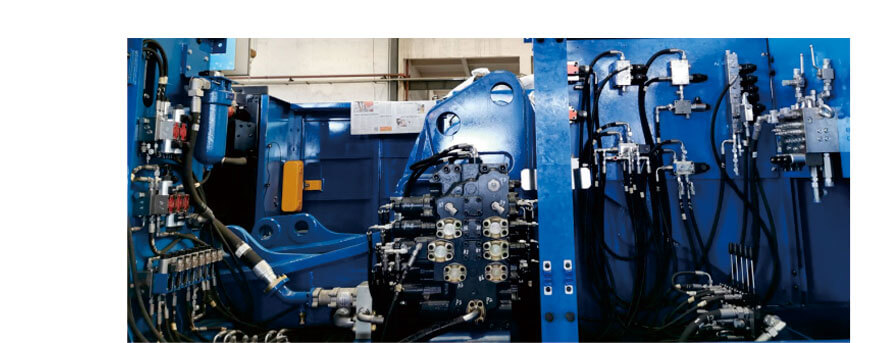

The main pump adopts international famous brand products with a flow rate of 2*380L/Min;

The MCV main valve is arranged longitudinally to facilitate installation and inspection of hydraulic hoses;

The counterweight is arranged horizontally for easy disassembly.

Internationally renowned brands of products:

Rexroth, Bucher, Kawasaki, Hengli, Sun, SKF, Parker...

The large diameter and long drum make the hoist have a large rope capacity, and the wire ropes are arranged in a single layer, which greatly improves the service life of the wire rope, greatly reduces the construction cost and reduces the labor intensity.

German Zollern reducer and brake, the maximum lifting force is 35t.

Rexroth variable motor, three-speed lowering speed: 50/55/60m/min, the fastest: 76m/min.

The driving seat is adjustable for long-term sitting comfort;

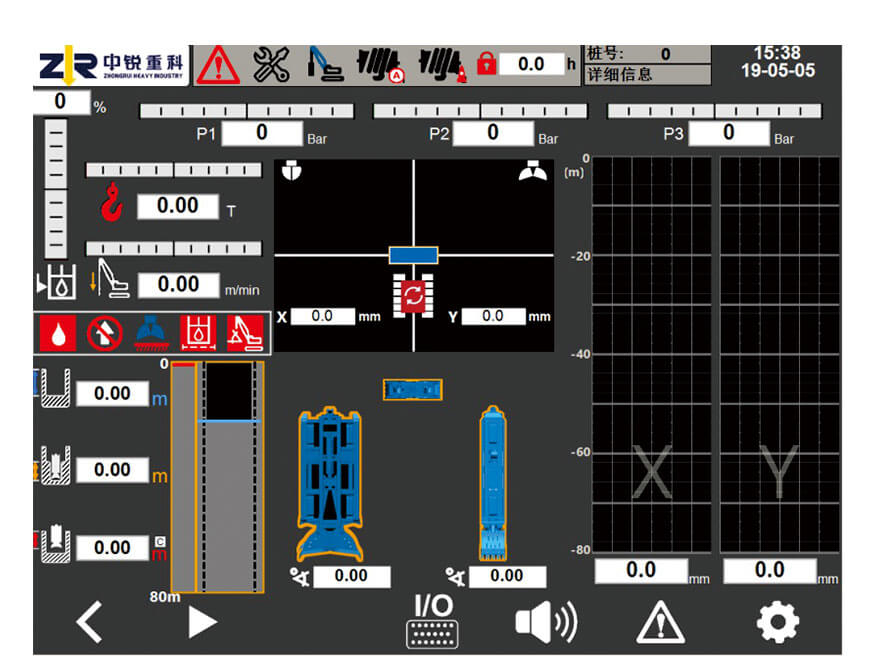

The monitoring system constantly displays various parameters of the equipment when it is working;

Built-in air conditioner, comfortable environment;

The multi-function operating handle imported from Germany integrates all the control functions of the equipment, with convenient operation and precise action.

12.1 inch imported EPEC monitor with a display area resolution of 1024×768, used to display equipment working information.

Equipment working voltage 9…36V, protection grade IP66, operating temperature range -30℃ ~ +70℃, brightness up to 600 cd/m2, contrast ratio 700:1;

The display is a capacitive touch screen and supports 16-bit true color display.

Advanced programmable PLC controller, inclinometer and correction system to ensure the quality of the groove.

The large memory, high-resolution touch screen monitors and records the operation process in real time and stores it all the time.

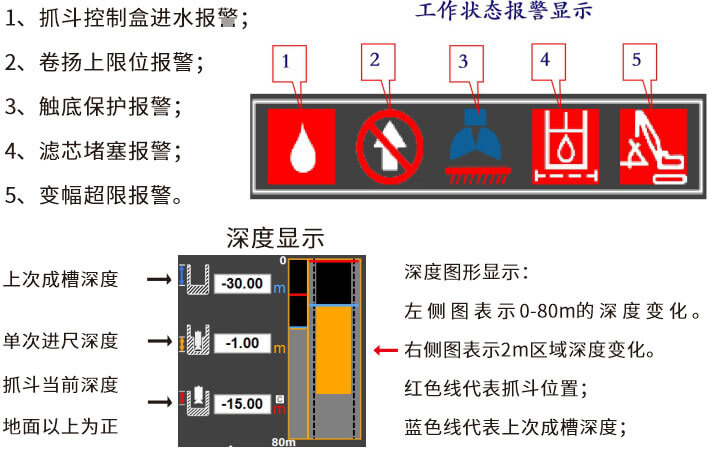

When an alarm state occurs during equipment operation, the corresponding icon will appear in the corresponding position and flash.

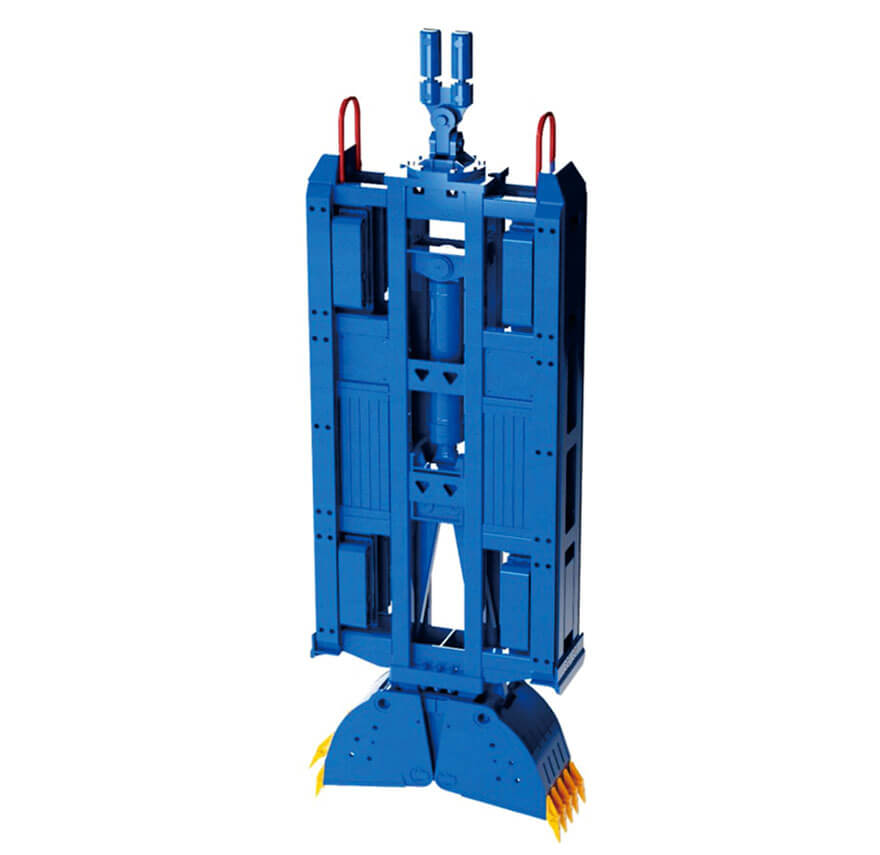

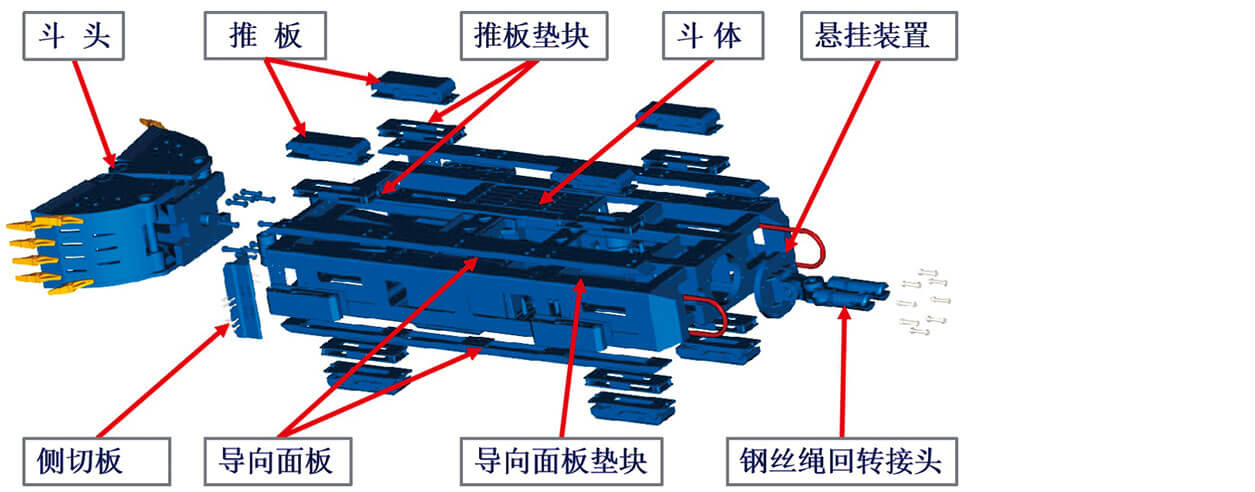

The multifunctional bucket body designed and developed according to construction experience has a simple structure and can easily adjust the weight of the bucket body for construction in different strata to achieve the best economic effect.

Groove width: 0.8~1.8m; The maximum closing force of the grab cylinder: 200t; The wear-resistant sleeve is reinforced and thickened, and the life is long;

The bucket body rotating device is optional for special-shaped groove construction; it can be equipped with an impact grab for hard ground construction;

The counterweight is optional 2~10 pieces; 735kg/piece.

Browse all major components

Browse all major components

View parameters

View parameters

View parameters

View parameters

View parameters

View parameters